Trust Tools From Carbide Drill Manufacturers

When it comes to milling and drilling tools, there are a lot of options on the market. Drill bits and cutters have to deal with a lot of heat and strain while they operate, which can cause failures in low-quality tools. If you want to ensure that your tools will last, you need to order your bits from Carbide Drill Manufacturers. Carbide tools offer superior wear resistance so they can help you take care of the toughest jobs without worrying about premature tool failure.

You may be wondering what makes carbide tools so special. At a glance, a carbide drill bit does not look very different from a steel drill bit. The big difference is obviously composition. Carbide may look like metal, but it is actually a type of material known as a cermet composite. This means that carbide drill manufacturers’ tool stock is actually a combination of ceramic carbide and a metal binder. The metallic appearance of carbide tools is the result of the cobalt metal binder which helps to hold the ceramic carbide powder together into a solid material. You can compare this material to the composition of concrete. Your metal is like the cement base, while the carbide is comparable to the stone aggregate, which is why this material is often referred to as cemented carbide. Together, these two materials become stronger than either would be on their own.

Carbide tools offer a much higher resistance to heat than metal tools because the ceramic carbide will not lose its strength and rigidity under high heat. When subjected to high heat, metal drill bits can lose their temper and the cutting edges will quickly soften and dull. Instead of suffering from this issue, the carbide tool will retain its edge and hardness under high heat, making carbide drills ideal for drilling into extremely hard materials and long working times.

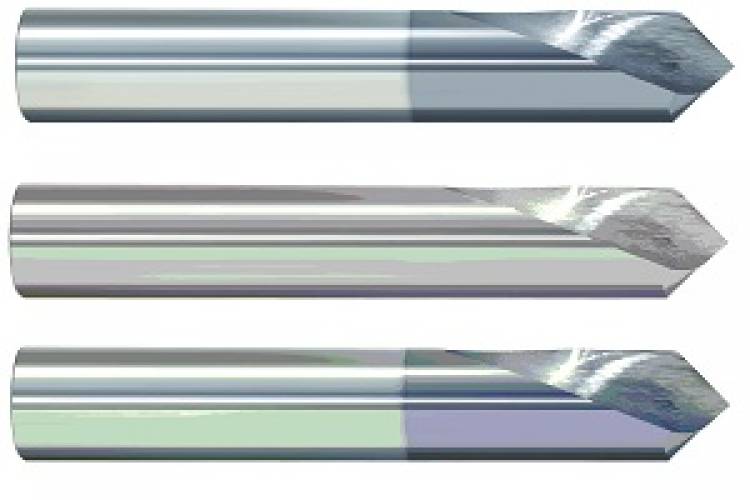

Here at Online Carbide, we manufacture several types of solid carbide drill bits. Our inventory includes both tradition and versatile jobber length drill bits as well as smaller bits like stub drills which are ideal for millwork. We also offer some more specialized bits including spot drills for priming holes in milled workpieces and center drills for machining and lathe work. For shops in need of versatile tools, we also offer drill mills that can perform a unique number of functions from axial cutting to side milling.

In order to ensure that our tools will last, we offer several of our drill bits with multiple coating options. Our standard bright finish is simply polished carbide. The polishing process helps ensure that the tool is smooth enough to evacuate chips easily while drilling. Our other coating option for our drill bits is our TiAlN coating. Titanium aluminum nitride is a thin dark coating that helps to protect tools from high heat. When heated, this coating will form a stable layer of hard aluminum oxide that helps to insulate the bit and deflect heat into the chips. This means that your drill bit will last longer and can run at faster speeds than an uncoated bit.

So if you need new bits for your shop, trust quality Carbide Drill Manufacturers. Here at Online Carbide, we only make our tools using the best solid carbide stock available. Instead of dealing with steel tools or cheaper carbide coated or tipped bits, experience the difference solid carbide can make. If you have any questions about our inventory, feel free to reach out to our team at 630-238-1424 or email us at [email protected].

For more information about Chamfer End Mill and Spot Drills Carbide Please visit : Onlinecarbide.